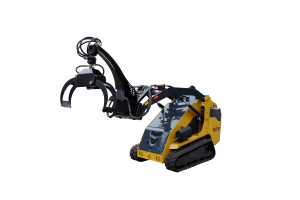

25hp Manufacturer small skid steer loader for construction industry

MINI SKID STEER Equipment has five model series available: the new 4 in1 bucket , the dedicated trencher and more series compact utility loaders, built to handle a full complement of more than 50 universal attachments. The standard quick-attach system enables the user to quickly and easily switch from a bucket to forks to auger or other tools for optimum on-the-job flexibility and bottom-line performance.

|

SPECIFICATIONS FOR ML525 MINI SKID STEER LOADER

|

|||

|

Engine

|

KUBOTA DIESEL Engine

|

3 cylinders

|

D1105

|

|

Displacement

|

1.13 L

|

||

|

Power

|

25 HP

|

||

|

Main performance parameters

|

Main performance parameters

|

km/h

|

5.9/4.0

|

|

Travel speed (max. & min.)

|

°

|

<=35

|

|

|

Max. Grade ability

|

rpm

|

11.3

|

|

|

Hydraulic system

|

Hydraulic Flow

|

gpm

|

14.5

|

|

Traveling Hydrostatic Pressure

|

bar

|

210.3

|

|

|

Fittings

|

Quick Coupler

|

||

Main Features

1) Simple structure in linear type ,easy in installation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) Great multiple job applications.

4) Running in a high automatization and intellectualization,no pollution

5)Changing attachments in seconds with no lifting.

PERFORMANCE

Operating Capacity (35%) ………………………………………………………………………………………………………………………. 291 kg

Operating Capacity (50%) ………………………………………………………………………………………………………………….416 kg

Tipping Capacity……………………………………………………………………………………………………………………………….832 kg

Weight (no attachment) …………………………………………………………………………………………………………………….1060 kg

Travel Speed …………………………………………………………………………………………………………………………………. 5.6 km/h

ENGINE/ELECTRICAL

Make/Model …………………………….. Kubota // D1105-E4B-CSR-1

Fuel/Cooling …………………………….. Diesel/Liquid Horsepower (SAE Gross) …………… 18.5kW

Maximum Governed RPM ………….. 3000 RPM

Torque @ 2200 RPM (SAE Net) ….. 71.5 Nm

Number of Cylinders 3

Displacement …………………………… 1.123L

Bore/Stroke ……………………………… 78mm/78.4 mm

Fuel Consumption …………………….. 6.1 L/h

Lubrication ………………………………. Gear Pump Pressure Crankcase Ventilation ……………….. Closed

Air Cleaner ………………………………. Dry replaceable cartridge with safety element

Ignition ……………………………………. Diesel-Compression

Engine Coolant …………………………. Propylene glycol/water mix (53%-47%)

with freeze protection to -37°C

Starting Aid ……………………………… Glow plugs

Alternator ………………………………… Belt Driven; 40 amps; Open

Battery ……………………………………. 12 V;45Ah

Starter …………………………………….. 12 volt;Gear Reduction Type; 1.4 kW

HYDRAULIC SYSTEM

Pump Type ……………………………………….. Engine driven, Two Gear type

Pump Capacity …………………………………. 53.4L/min@ 3000 RPM

System Relief @ Quick Couplers …………. 210 Bar

Hydraulic Filter ………………………………….. Full flow replaceable, 10 micron synthetic media element

Hydraulic Cylinders ……………………………. Double-acting

Main Control Valve …………………………….. 5-Spool, open center series parallel configuration

Attachment Control Valve…………………. 2-Spool, open center series parallel configuration

Bore Diameter

Lift Cylinder (2) ……………………………. 45mm

Tilt Cylinder (1) ……………………………. 55mm

Rod Diameter

Lift Cylinder (2) ……………………………. 25 mm

Tilt Cylinder (1) ……………………………. 30 mm

Stroke

Lift Cylinder (2) ……………………………. 295 mm

Tilt Cylinder (1) ……………………………. 280 mm

Hydraulic Function Times

Raise Lift Arms ……………………………. 3.5 Seconds

Lower Lift Arms ……………………………. 2.4 Seconds

Bucket Dump ………………………………. 2.5 Seconds

Bucket Rollback …………………………… 1.8 Seconds

DRIVE SYSTEM

Main Drive ………….. Fully hydraulic rubber track drive

Transmission ………. Direct drive of hydraulic motor to main undercarriage drive sprocket Tracks ……………….. 200 mm wide

Rollers……………..5 Each side

Pressure ………….. 25.3 kPa

CAPACITIES

Cooling System ………………………………. 5.2 L

Fuel Tank ………………………………………… 35 L

Engine Oil with Filter ………………………… 5.1L

Hydraulic Reservoir ………………………. …34 L

Hydraulic System …………………………. ….40 L

CONTROLS

Vehicle Steering ………………. Direction and speed controlled by two handle

Lift & Tilt …………………… Controlled by one hand lever

Front Auxiliary (Std.) …… Controlled by one hand lever

Auxiliary Pressure Release .. Fore and aft movement of hand lever after engine has been shut off.

Engine …………………………… Hand lever throttle: Key-type starter switch and shutdown

Starting Aid …………………….. Glow Plugs – Activated by key switch

INSTRUMENTATION

The mini track loader conditions are monitored by a combination of gauges and warning lights in the operator’s line of sight that monitor the following functions. The system shall alert the operator of

monitored loader malfunctions by way of an visual warning lights.

1.Is SITC a manufacture or trading company ?

SITS is a group company , include five middle-sized factory ,one high technology developer company and a professional internation trade company. Supply from design — production — publicity — sell –after sell work all the line service team .

2.What’s the main products of SITC ?

SITC mainly support construction machinery , such as loader , skid loader , excavator , mixer , concrete pump , road roller , crane and etc.

3.How long is the warranty period ?

Normally , SITC products have one year guarantee period .

4.What is the MOQ ?

One set .

5.What’s the policy for the agents ?

For agents ,SITC supply the dealer price for their area , and help to do advertising in their area , some exhibitions in agent area also be supplied . Each year , SITC service engineer will go to the agents company to help them tread the technical questions.